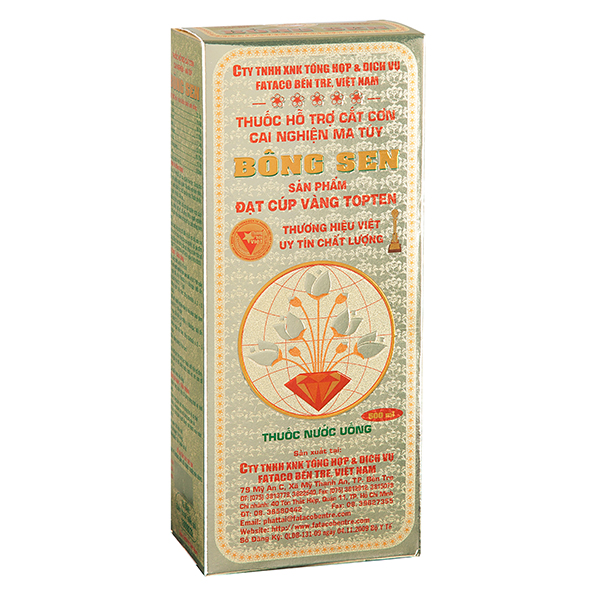

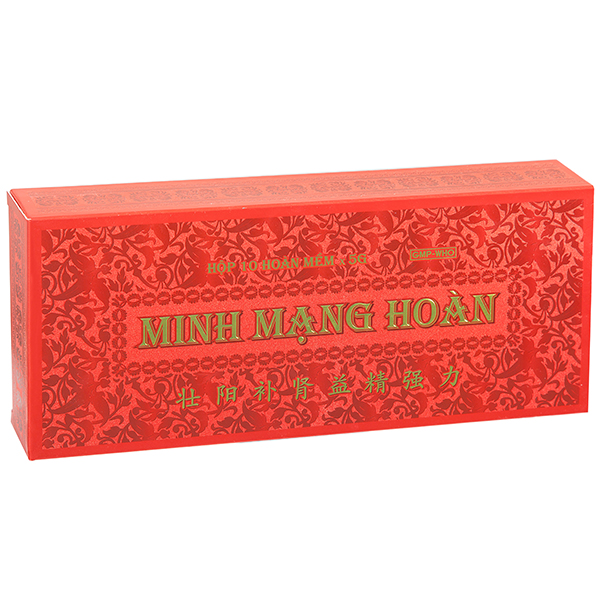

our products

-

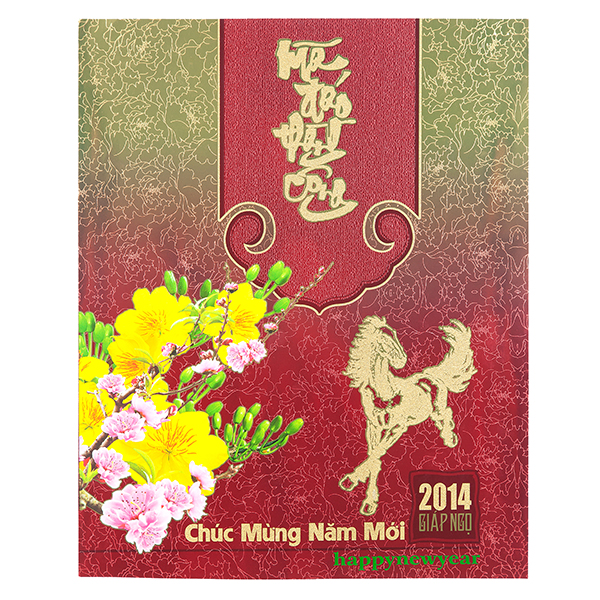

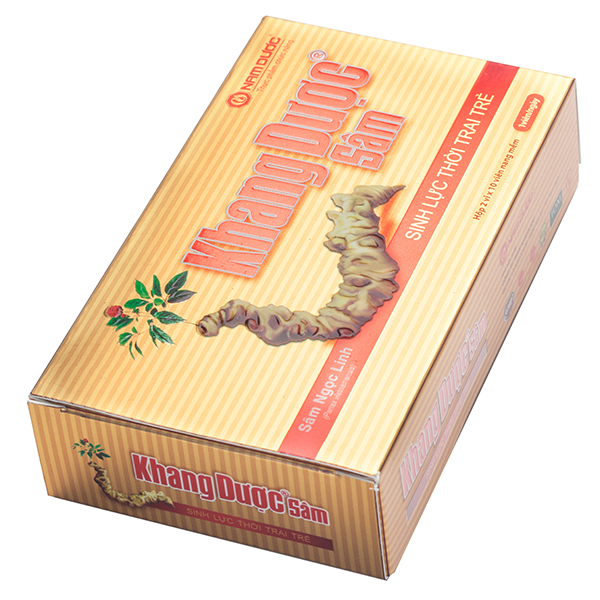

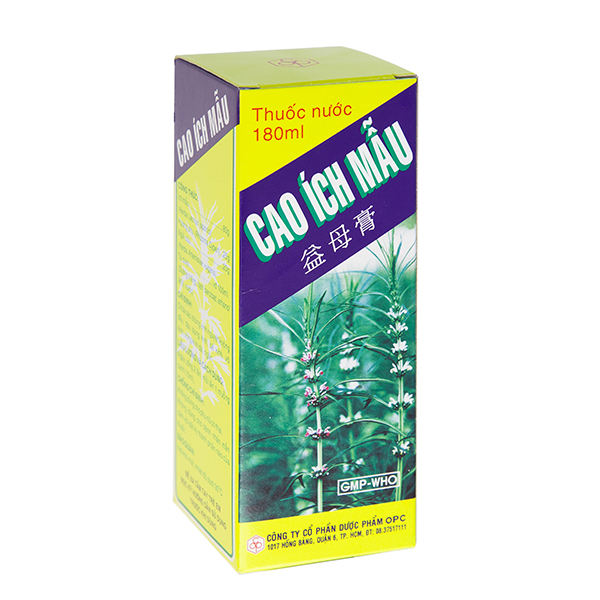

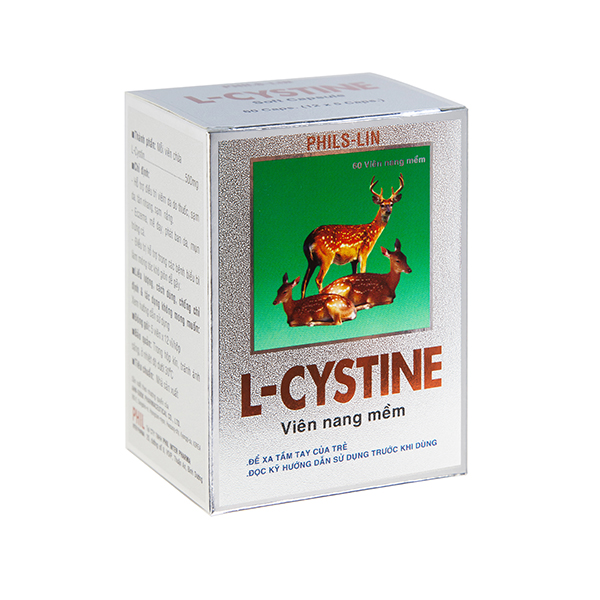

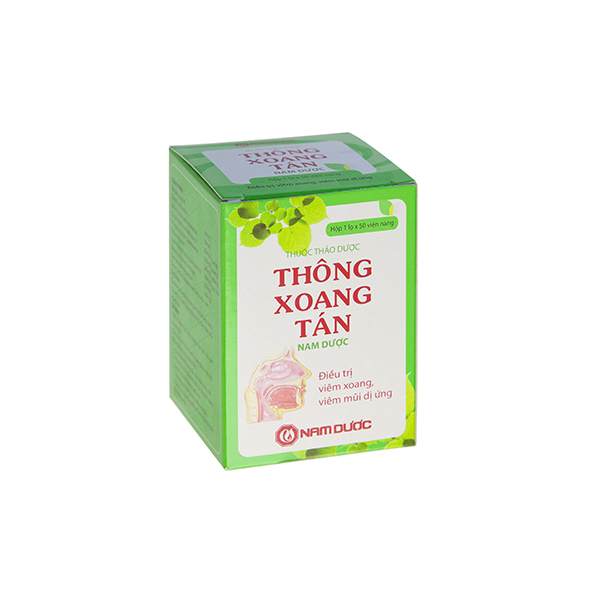

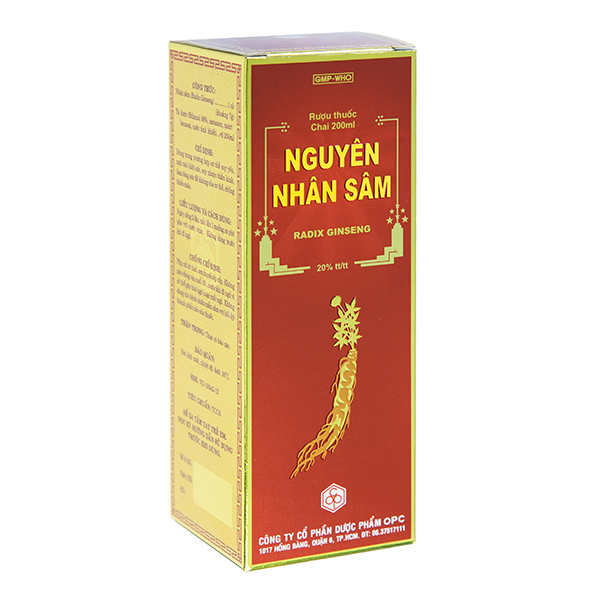

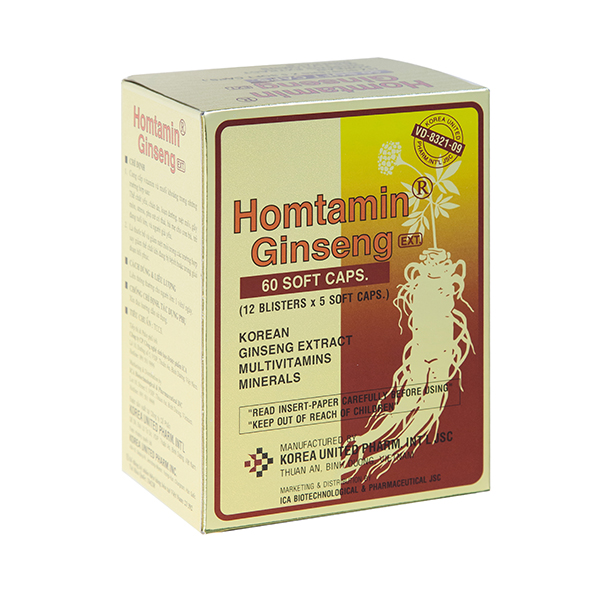

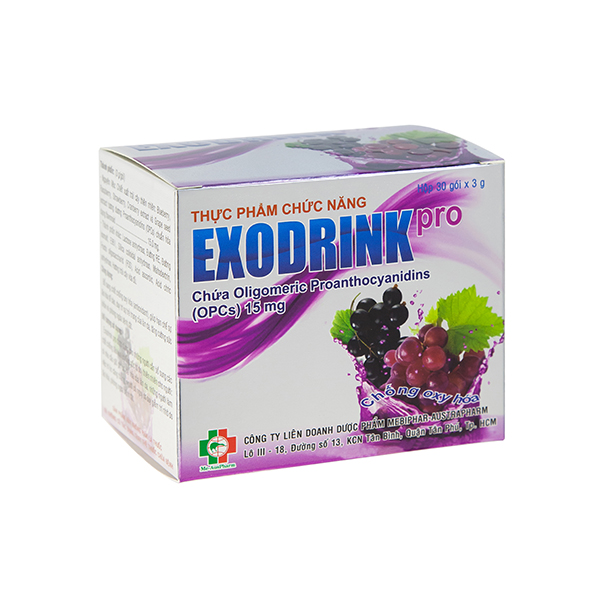

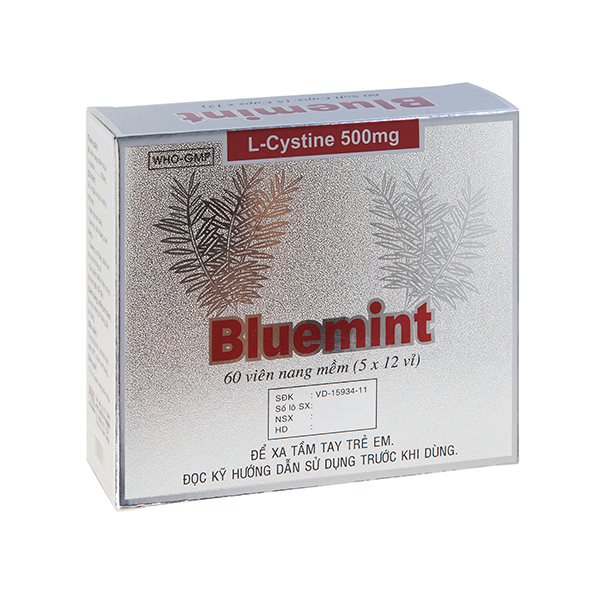

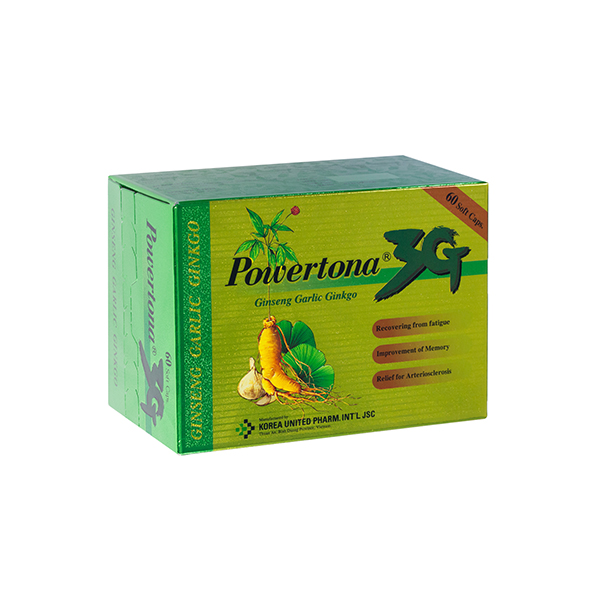

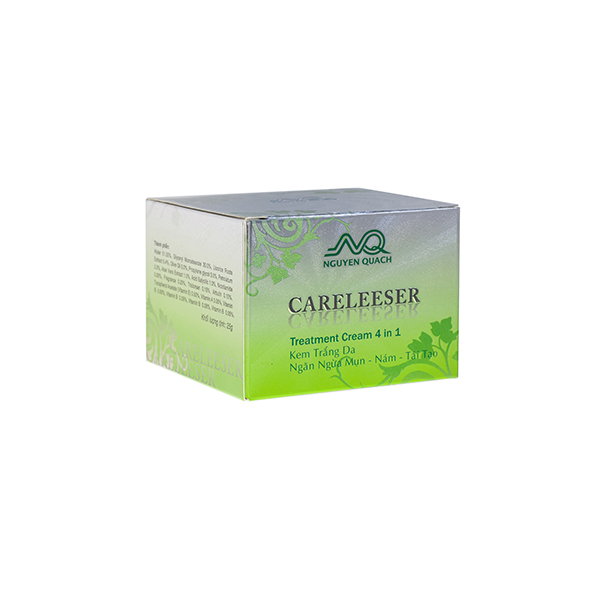

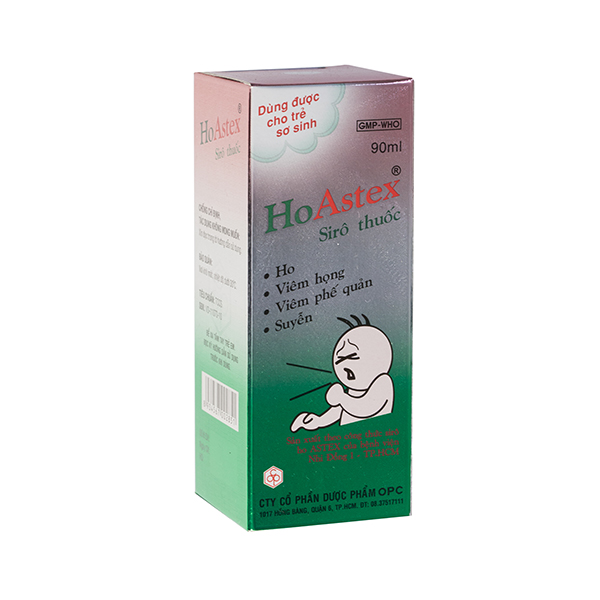

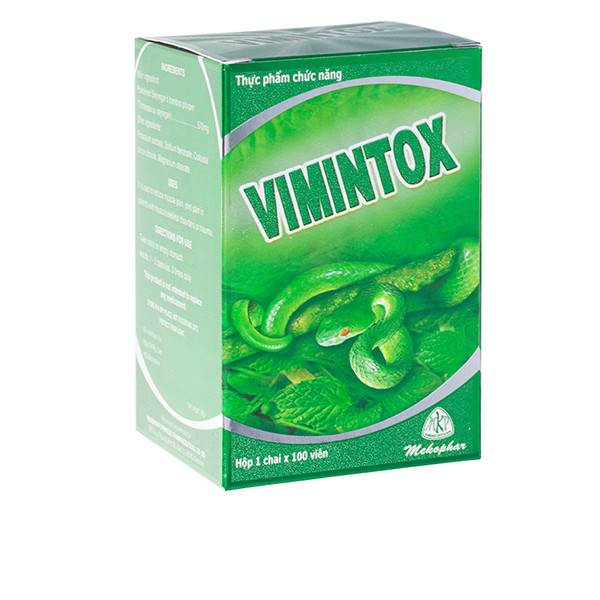

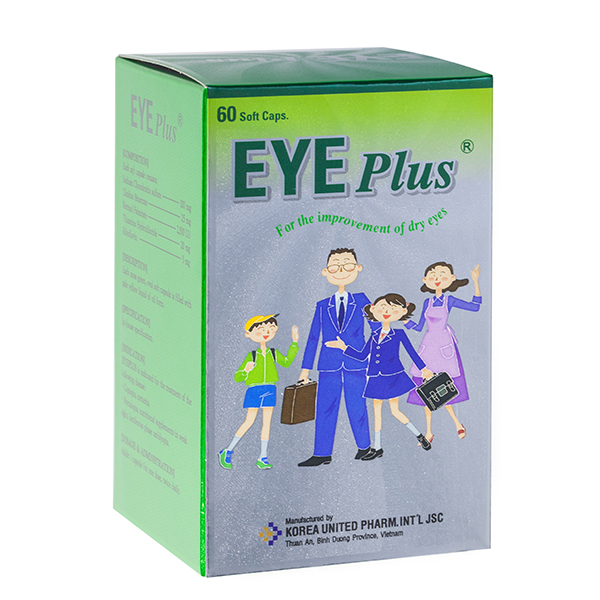

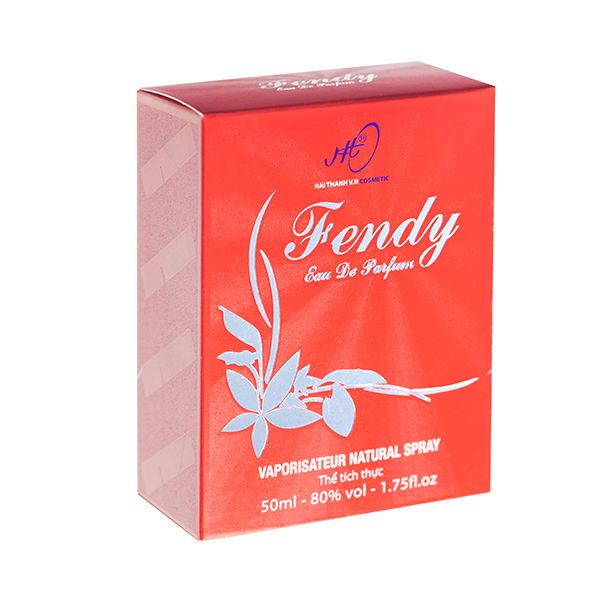

Paper box

-

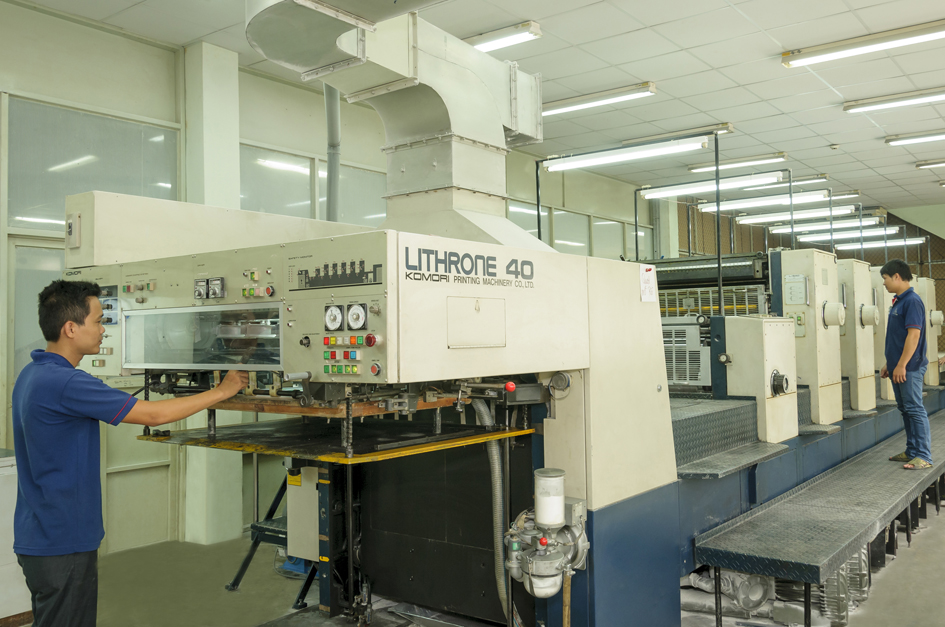

prepress

prepress

Includes designing, filming, color-proof checking and proofreading. Every step needs to be approved by clients before moving to the next one.

Towards regular clients, technique parameters of each product have to be saved in the internal system, thus, providing stable quality, work efficiency and less time-consumption for reorders.

-

Paper

cutting - press

-

post-press

post-press

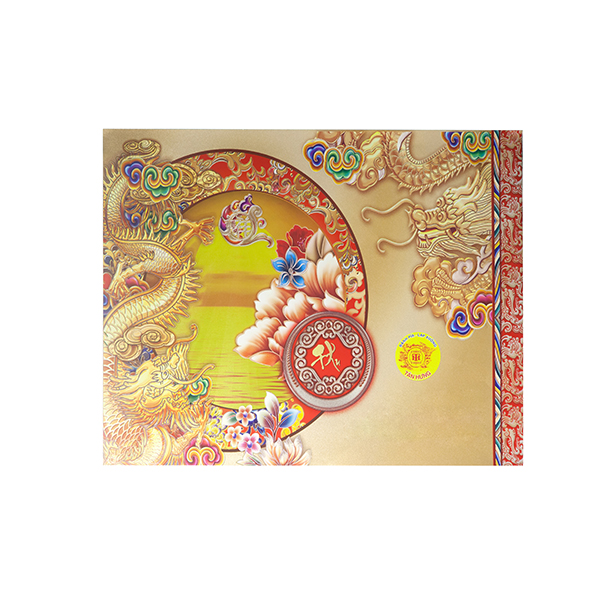

Includes coating and laminating, post-press effects, die-cutting, folding and gluing.Post-press effects: 3D lightening, sparkling, UV spot, hot stamping and embossing.

- Various and customized designs.

- The image is moving when looking at from different angles.

- Applied in both metalized products and paper products.

- All effects could be combined together in a design.

-

quality

controlquality control

Strictly building up the general quality-control system.

Every worker has to carefully inspect EVERY SINGLE PART OF THE FINAL PRODUCT following the quality-control standards for a guaranteed quality and homogeneousness products and services. Diminishing ratio is based on the number of products. However, it is only allowed 7% and lower for metalized boxes and 2% and lower for paper boxes.

Quality-control standards will be various to different partners and clients.

-

packing

&

deliverypacking & delivery

The delivery time vary and depends on the production situation and requirements of clients at the time, in order to avoid late delivery. However, the minimum timing is 5 days for reorders and 7-10 days for new orders after receiving final approval confirmation.

-

prepress

-

Paper cup

The company prints paper-cup packaging and produces paper cups.

Origin of paper:

Thailand and Korea

Material:

paper + PE

Paper weight (gsm):

280/ 250/ 210 + 18 (1 PE / 2 PE)

Model availability:

5oz/ 8oz/ 12oz/ 16oz

Type: hot and cold cup

- Hot cup: dribble or bubble jacket designs. These jackets help consumers do not feeling hot when holding the cups.

- Cold cup: without any jacket.

Pieces/ per carton:

1000