This includes design, film output, color-proof printing, and layout. All steps require client approval.

For regular customers, the technical specifications of each product are stored in the internal system, thereby ensuring quality, work efficiency, and saving time for subsequent orders.

The paper is imported from Indonesia, Thailand, and Taiwan.

This includes lamination, post-printing effects, box die-cutting, box folding and gluing, and product quality control.

Post-printing effects: in 3Dlight, foil stamping and embossing.

- Diverse designs and customized options available.

- The 3D effect moves when the product is in motion.

- Suitable for use on both metallized and regular paper.

- All effects can be combined in the same design.

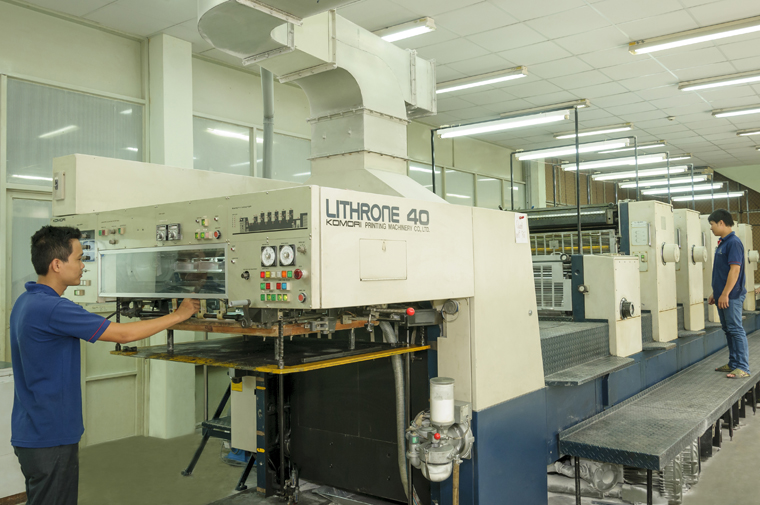

Choose the right printer for each type of product.

Delivery times may vary and depend on production status and customer requirements at the time, in order to avoid delays. However, the minimum time is 5 days for repeat orders and 7-10 days for new orders after receiving final approval confirmation.

Establish a rigorous inspection system.

Workers must inspect EACH FINISHED BOX according to established standards… to ensure quality and consistency. The allowable loss rate is 7% for boxes printed on metallized paper and 2% for boxes printed on regular paper.

Depending on the customer's requirements, the quality control standards can be adjusted accordingly.